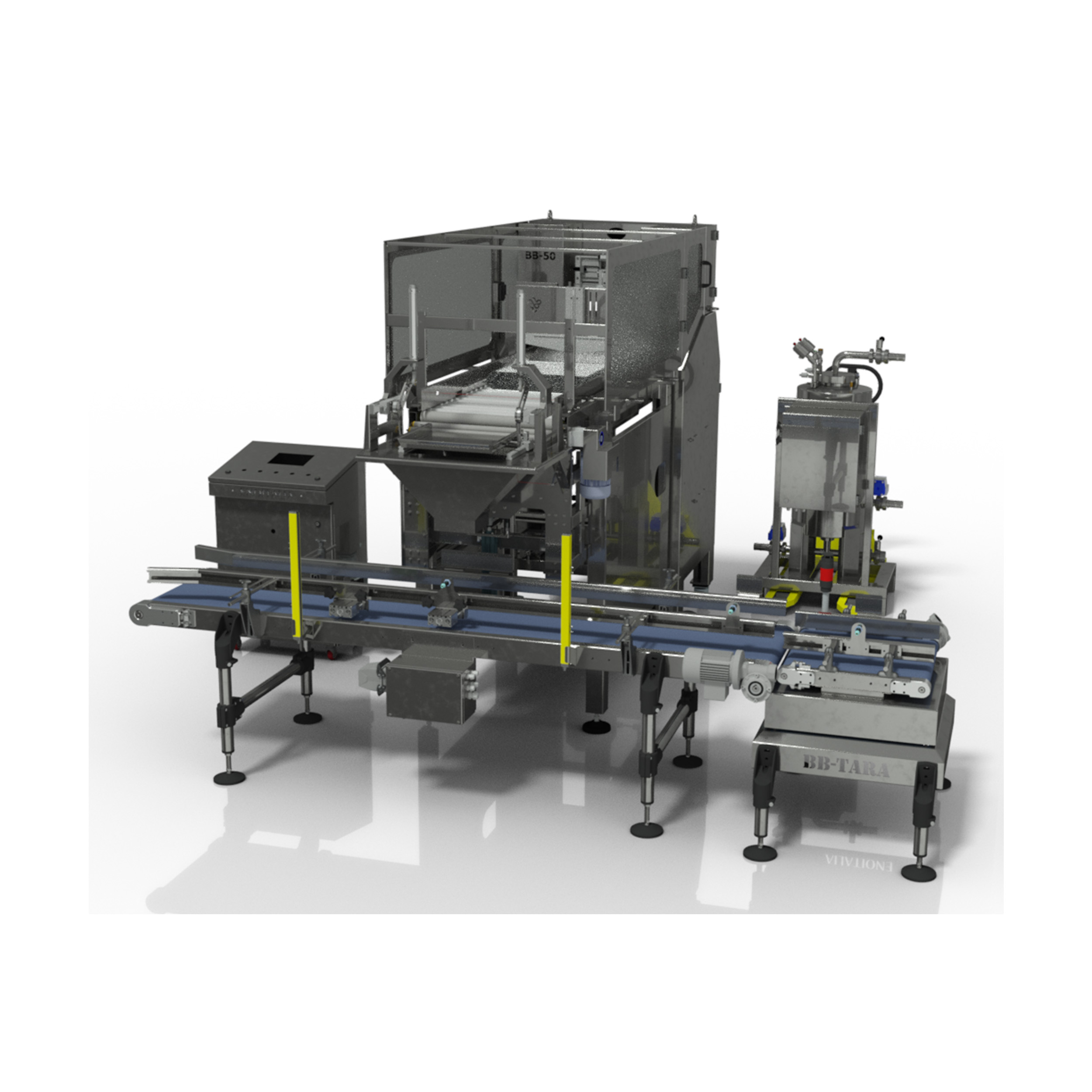

Fully automatic machine, it manages the filling, cutting and packaging operations of the bags.

Set up as standard to work with food liquids (wine, oil, fruit juices) both at room temperature and at 100 ° C; it can be used with creams, sauces, with suspended solids or with industrial liquids (lubricating oils, soaps).

The filler consists of three filling modules (where the management of the opening, dosing and closing of the bag takes place); cutting and dragging (by means of a motorized roller conveyor); packaging and transport.

High reliability thanks to the use of SIEMENS electronics and SMC pneumatics.

The remote control panel on wheels allows the operator to quickly manage all the phases, varying the container sizes (from 1 to 20 liters), the dosage calibrations and the working speed in a few steps.

It is possible to integrate the machinery with an isobaric type dosing system, to keep the treated products unaltered, simplifying calibration management and reducing machinery maintenance.

Possibility of setting up the filler with different integration solutions with the production cycle of the cellar, leaving a wide choice of the type of initial investment: manual loading of the cartons, manual handling of the filled containers, manual closing of the boxes, are all options that can be evaluated in alternative to the automatic cycle.

SAFETY: total protection in the use of the machinery with the provision of safety barriers and timed control circuits.

RELIABILITY: as standard the machine is equipped with a REMOTE REMOTE ASSISTANCE module; possibility of checking the functioning of the single components, guaranteeing a quick repair intervention.

SIMPLICITY: the filling cycle is programmable, the touch screen control panel and the motorization of the work surface allow the machinery to be managed in a few moments both in filling operations and in washing and sanitizing operations.

PRECISION: the SIEMENS PLC control panel allows you to manage all the filling phases, adapting the machine to any type of liquid treated (wine, fruit juices, oil, water, creams, etc.).

The AUTOTUNING function allows automatic calibration of the machinery, eliminating the need to carry out countless samples. Repeatability of volumes with an error of ± 0.2%.

SPEED: all the operations carried out by the filler are set by the operator on the basis of their needs: vacuum time, gas injection times, filling speed, bag opening and closing speed.

The machine is supplied as standard equipped with a 9500 l / h self-priming volumetric pump with rubber impeller and speed regulation inverter.

CLEANING: The machine can be sanitized with a CIP circuit using the special stainless steel tap and the automatic program. Furthermore, the machine is designed to perform 110 ° C steam sanitization.

OTHER ADVANTAGES: use of self-priming volumetric pumps with complete emptying circuit; stainless steel induction meter; 7 “display; installation of a 200 liter storage tank for the management of continuous filtration systems (OPTIONAL); multilingual programming; control panel on transportable platform.

| Model | Fitting | Power | Capacity 5 lt/h | Capacity 10 lt/h | Capacity 20 lt/h | Engine Hp (Kw) | Dimension (mm) | Weight |

| 9450 | Triclover da 1,5″ | Trifase 380V 5 Poli - 50Hz | 480 | 300 | 250 | 2,5 Kw | 3300x1100x2500 | 650 Kg |